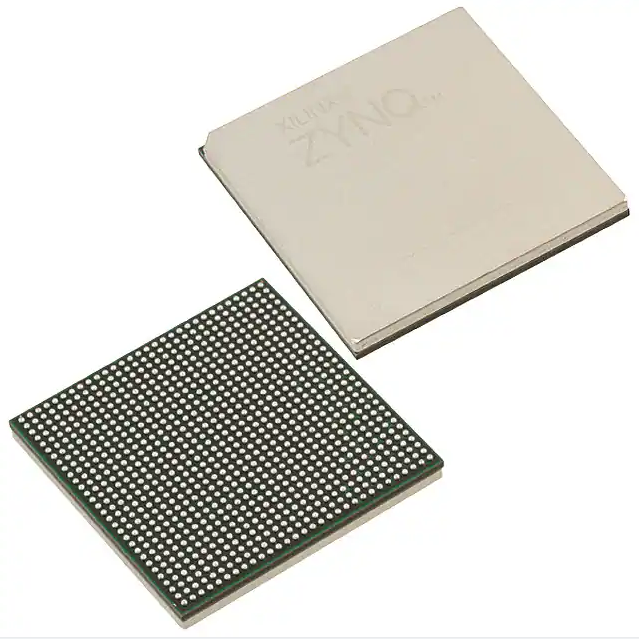

Electronic Components Reliable quality IC MCU chip integrated circuit IC SOC CORTEX-A53 900FCBGA XCZU4CG-2FBVB900I

Product Attributes

| TYPE | DESCRIPTION |

| Category | Integrated Circuits (ICs)Embedded |

| Mfr | AMD Xilinx |

| Series | Zynq® UltraScale+™ MPSoC CG |

| Package | Tray |

| Standard Package | 1 |

| Product Status | Active |

| Architecture | MCU, FPGA |

| Core Processor | Dual ARM® Cortex®-A53 MPCore™ with CoreSight™, Dual ARM®Cortex™-R5 with CoreSight™ |

| Flash Size | - |

| RAM Size | 256KB |

| Peripherals | DMA, WDT |

| Connectivity | CANbus, EBI/EMI, Ethernet, I²C, MMC/SD/SDIO, SPI, UART/USART, USB OTG |

| Speed | 533MHz, 1.3GHz |

| Primary Attributes | Zynq®UltraScale+™ FPGA, 192K+ Logic Cells |

| Operating Temperature | -40°C ~ 100°C (TJ) |

| Package / Case | 900-BBGA, FCBGA |

| Supplier Device Package | 900-FCBGA (31×31) |

| Number of I/O | 204 |

| Base Product Number | XCZU4 |

Shutdowns and production cuts! What is the reason for the chip shortage?

Recently, OFweek Electronic Engineering learned that Japanese automaker Subaru has announced that the company will be making production adjustments due to problems in the chip supply chain.

Subaru was scheduled to take a holiday to shut down production during the Japanese Golden Week holiday on April 28, 2021, and resume work on May 10. Due to problems with the chip supply chain, production operations will be suspended 13 working days earlier, starting on April 10, in line with the decision to reduce production. This means that the original two-week shutdown will be extended to one month.

Subaru’s decision to reduce production will have an impact on the Yajima plant in Gunma, Japan, which is responsible for the Productivity Lion sedan and Forester SUV. Subaru has already decided to cut production by around 48,000 units for the current fiscal year due to a lack of cores, and this decision to reduce production will add another 10,000 units to that figure. In a statement, Subaru noted: “The extent of the impact of the production cut on the company’s performance for the full fiscal year cannot yet be determined. We will make further announcements if necessary.”

The number of automakers that have had to cut production due to chip shortages is currently continuing to grow, hitting almost the entire industry. This shows that the impact of the semiconductor chip shortage on the global automotive market is severe.

According to incomplete statistics, since the second half of 2020, the world has set off a wave of the automotive supply chain “chip shortage”, due to the lack of core shutdown production of car companies have been up to dozens of, and intensified.

Ford – On 6 April, Ford announced that several plants in North America will be shut down for several weeks and planned overtime at several plants will be canceled. From reports in foreign media, it appears that the shortage of automotive chips will affect Ford’s six plants in North America.

Nissan – Nissan plans to suspend production work at the Smyrna auto plant in Turkey, the Canton auto plant in the US, and the Aguascalientes auto plant in Mexico from April.

Hyundai – Hyundai has previously adjusted production by reducing overtime at each plant, but the IONIQ 5 and KONA production lines at the first Ulsan plant will still be suspended from 7 to 14 April to cope with the lack of capacity.

Suzuki – On 5 April, Suzuki Motor announced that two of its three plants in Japan, located in Shizuoka Prefecture, would be temporarily suspended, again due to a shortage of chip supply. This is the first time Suzuki has shut down production due to a shortage of chip supply. However, Suzuki said there are no plans to cut production for the time being and they will maintain plant operations during the holiday season to make up for the loss of production.

Azera – New car maker Azera (NIO) announced that it has decided to suspend production at its Hefei Jianghuai Azera manufacturing plant for five working days from 29 March due to a chip shortage. During its annual report conference call in March, Azera founder and CEO Li Bin said, “Chip supply did have some impact on the second quarter, and at the moment it can meet normal production demand, but the risk is high.”

North and South Volkswagen – FAW-Volkswagen and SAIC-Volkswagen have become the first car companies to bear the brunt of the wave of core shortages in the country. Earlier this year, after the chip factories were shut down due to the overseas epidemic, high-end chips for vehicles, mainly ESP and ECU chips, were out of stock and out of order, resulting in the import of corresponding parts being blocked, thus leading to production stoppages. Most of the domestic high-end models above the car manufacturers affected by the most obvious are expected to be affected by the production capacity of more than a million vehicles.