Electronic Component – TPS54625PWPR

Product Attributes

|

TYPE |

DESCRIPTION |

|

Category |

Integrated Circuits (ICs) PMIC - Voltage Regulators - DC DC Switching Regulators |

|

Mfr |

Texas Instruments |

|

Series |

D-CAP2™ |

|

Package |

Tape & Reel (TR) Cut Tape (CT) Digi-Reel® |

|

Product Status |

Active |

|

Function |

Step-Down |

|

Output Configuration |

Positive |

|

Topology |

Buck |

|

Output Type |

Adjustable |

|

Number of Outputs |

1 |

|

Voltage - Input (Min) |

4.5V |

|

Voltage - Input (Max) |

18V |

|

Voltage - Output (Min/Fixed) |

0.765V |

|

Voltage - Output (Max) |

5.5V |

|

Current - Output |

6.5A |

|

Frequency - Switching |

650kHz |

|

Synchronous Rectifier |

Yes |

|

Operating Temperature |

-40°C ~ 85°C (TA) |

|

Mounting Type |

Surface Mount |

|

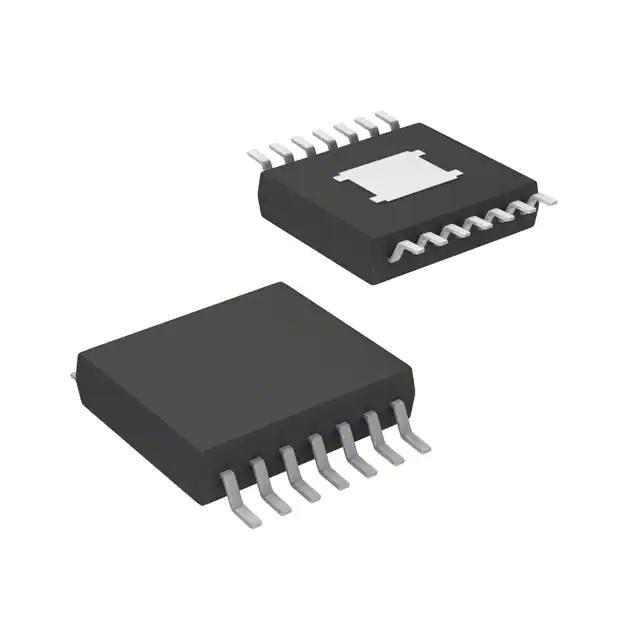

Package / Case |

14-TSSOP (0.173", 4.40mm Width) Exposed Pad |

|

Supplier Device Package |

14-HTSSOP |

|

Base Product Number |

TPS54625 |

|

SPQ |

2000/pcs |

Basic classification

1. Alternator voltage regulator can be divided into: according to the working principle:

(1) Contact voltage regulator

Contact voltage regulator is applied earlier, this regulator contact vibration frequency is slow, there is mechanical inertia and electromagnetic inertia, low voltage regulation accuracy, contact easy to produce sparks, large radio interference, poor reliability, short life, has been eliminated.

(2) Transistor regulator

With the development of semiconductor technology, transistor regulators have been adopted. Its advantages are: the transistor switching frequency is high, and does not produce sparks, high adjustment accuracy, but also has the advantages of light weight, small size, long life, high reliability, small radio interference, etc., and is now widely used in Dongfeng, Jiefang and a variety of low-end models.

3) Integrated circuit regulator

In addition to the advantages of transistor regulators, integrated circuit regulators are also ultra-small, mounted inside the generator (also known as built-in regulators), reducing external wiring, and the cooling effect has been improved, and is now widely used in Santana. Audi and other sedan models.

(4) Computer-controlled regulator

After measuring the total load of the system by the electric load detector, the signal is sent to the generator computer, and then the generator voltage regulator is controlled by the engine computer, and the magnetic field circuit is turned on and off in a timely manner, that is, the normal operation of the electrical system can be reliably guaranteed, the battery can be charged sufficiently, and the engine load can be reduced and the fuel economy can be improved. For example, Shanghai Buick, Guangzhou Honda and other car generators use this regulator.

2. Voltage regulator

According to the matching alternator iron type can be divided into:

(1) Inner iron type regulator

The voltage regulator suitable for matching with the internal tie-type alternator is called the internal tie-type regulator;

(2) External iron type regulator

The voltage regulator suitable for matching with the external tie-type alternator is called the outer tie-iron regulator.

In the process of use, for the transistor regulator, it is best to use the regulator specified in the car manual, if other models are used to replace, in addition to the nominal voltage and other specified parameters and the original regulator is the same, the substitute regulator must be the same as the original regulator's iron form, otherwise, the generator may not work properly due to the excitation circuit. For integrated circuit regulators, they must be dedicated and cannot be replaced.

Use maintenance

Use maintenance

The regulator is generally not allowed to disassemble the cover during use, and the normal situation is to carry out a comprehensive inspection and maintenance every 200h or so, and its content is as follows:

1.Remove the case and inspect the contact surface for dirt and burn damage. If there is dirt, wipe the contact surface with a cleaner paper. If the contact is ablated or uneven and the contact is poor, it is generally smoothed with "00" sandpaper or sand strip, and finally wiped with clean paper.

2.Check the firmness of each connector, measure the resistance and the resistance value of each coil. If there is damage, it should be repaired or replaced with a new part in time.

3.Check the closing voltage and back current of the current breaker, the limit voltage of the voltage reducer, the limit current of the current limit of the current stopper, and the gaps and air gaps of various contacts. If it does not meet the requirements, it should be adjusted.

4.Check the adjusted regulator and pay attention to the indication of the charging ammeter pointer when starting the diesel engine. If the needle of the ammeter is still pointing to the "-" side when the diesel engine is running at a medium speed or above, this means that the contact of the current breaker is not disconnected, and the ground switch should be quickly disconnected; Otherwise, it will damage the battery, regulator, charging generator, etc. If the needle of the ammeter still points to "0" after the diesel engine starts to the rated speed, the adjustment of the description is not adjusted according to the technical requirements, and it should be re-checked and adjusted.